the fastrip line

MACHINERY

The Fastrip® line of machines offers fully customizable solutions that adapt to your needs. Whether integrated into existing production lines or used as a standalone unit, Fastrip® supports businesses looking to expand into professional paint stripping.

Fastrip T5 Multi-Tank

Dipping Stripping System

Fastrip T5 Multi-Tank is a medium-sized chemical stripping system – 210-gal capacity – designed to recover metal components before recoating.

System Overview

Parts are loaded into custom baskets and transferred into the T5 stripping tank. The stripped material is then moved to the rinsing tank, where a trolley-mounted pump allows for a final spray rinse. After rinsing, the material goes to the drip tank, which serves as the loading /unloading station.

Designed for ease of use and safe operation, the tank can be moved by forklift and is optimized for industrial workflows.

Benefits and Performance

Optional integrations include ultrasonic systems or mechanical agitators to improve performance, a fume extraction system, and additional workpiece baskets.

Dipping Stripping Tank

Fastrip T5 is a medium-sized immersion tank with a 210-gallon capacity, designed to remove coatings from ferrous metals and light alloys.

System Overview

Built with a double-wall “tank within a tank” structure, it ensures secure fluid containment and long-lasting durability. The system combines chemical and mechanical action, supported by an integrated electric heating system. The tank is insulated on all sides and equipped with an interlock cover. It’s also pre-configured to connect to a fume extraction system.

Benefits and Performance

Optional accessories include custom workpiece holders and a fume extraction unit.

Fastrip T5

FASTRIP ISP

Inline Chemical Stripping System for Hooks and Racks

Fastrip ISP is an inline system designed to strip hooks and racks used in electrostatic powder coating lines.

System Overview

The system consists of a horizontal tank that integrates with an existing overhead conveyor for inline hook movement. At the end of the cycle, hooks and racks are immersed in the stripping bath for approximately 2 minutes. Once cleaned, they are ready for the next loading batch. No manual labor required.

Fastrip ISP operates at low temperatures (120°F) and is safe for all metals, including light alloys.

Benefits and Performance

A clean hook ensures maximum electrostatic charge transfer during the powder coating application, improving paint adhesion and surface finish quality.

Vertical Chemical Stripping System for Metal Parts

Fastrip S is a vertical stripping spray system for metal parts. It is designed as a compact, off-line stripping station.

System Overview

The system consists of a spray chamber where parts are placed in customizable baskets and introduced for stripping. The system runs stripping cycles at temperatures between 175°F and 300°F, programmable based on the material and type of coating to be removed. Rinsing can occur inside the machine or through a dedicated secondary unit.

Fastrip S strips parts made of iron, steel, and light alloys without damaging their surfaces.

Benefits and Performance

To further extend the life of the stripping solution, Fastrip S can be paired with FASTRIP FP filtration systems.

FASTRIP S

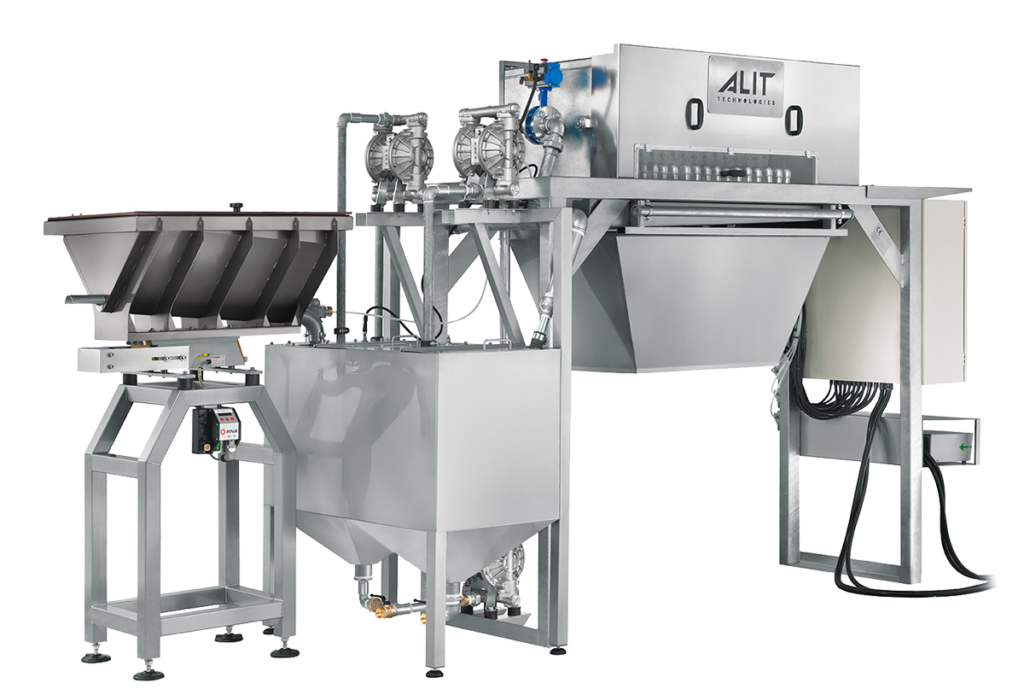

FASTRIP fp

Filtration Unit for Stripping Systems

Fastrip FP is a stainless steel filtration system engineered to work alongside chemical stripping tanks. It keeps the stripping bath clean and performant over time.

System Overview

The system includes a filter press to separate sludge from the solution, an automatic dosing unit for adding ALITFLOCK flocculant, and two tanks:

• A sedimentation tank with a cone-shaped bottom

• A recovery tank that collects the filtered solution for reuse

Benefits and Performance

Fastrip FP boosts filtration performance, reduces the frequency of chemical bath replacement, and extends the lifespan of your stripping solution.

Offline Paint Stripping System for Aluminum Profiles

Fastrip AP is a compact chemical stripping system designed specifically for aluminum profiles. It can handle profiles weighing up to 550 lbs and measuring up to 26 feet in length.

System Overview

Profiles are loaded into the stripping tank where chemical agents remove the paint, typically within about 3 hours depending on the type and thickness of the coating. After stripping, the profiles are transferred to the rinsing tank for thorough cleaning. The system is equipped with a safety laser bar, surrounding wire mesh, a fume extraction system, and an automatic lid

Benefits and Performance

Optimal performance can be achieved using Fastrip AP in combination with Metalstrip 1333/1, a low environmental impact alkaline paint stripper that extends bath life.

FASTRIP AP

FASTRIP MT

Chemical Stripping System for Powder-Coated Aluminum

Fastrip MT is a chemical stripping system designed to recover aluminum profiles with coating defects, preparing them for repainting. It provides a cost-effective alternative to scrapping or manual sanding.

System Overview

The system includes a series of immersion tanks, a bridge crane for part handling, and a side catwalk for easy supervision. The process starts with a heated stripping bath (120–130°F), followed by a room-temperature rinse. Parts then move through an alkaline pickling stage (105–120°F), a second rinse, an acid neutralization bath, and a final rinse.

Benefits and Performance

Ideal for recovering profiles used in windows and doors, shower enclosures, screens, automotive parts, and signage.

Paint Stripping Tank with Mixer Technology

Fastrip T2-120 MIX is a robust stripping system that removes coatings by combining chemical action and hydrostatic pressure generated by an integrated mixer.

System Overview

Instead of ultrasound, the system relies on a powerful mixer that circulates the stripping solution, creating a gentle and effective mechanical action on the parts in the tank. The absence of ultrasound reduces heat stress on internal electronics, extending system life and reliability.

Benefits and Performance

This design reduces noise and allows the system to operate even with contaminated solution.

FASTRIP T2 120-MIX

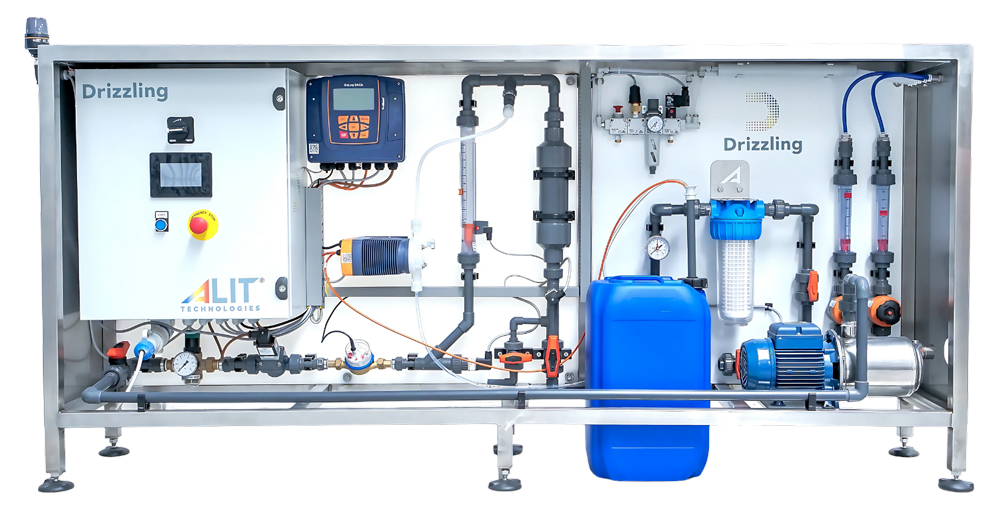

Drizzling

Dosing System for Chrome-Free Metal Treatment

DRIZZLING is a precision dosing system designed to apply chrome-free conversion coatings on metal components.

System Overview

Drizzling continuously mixes demineralized water with chrome-free conversion coating product to create a fresh solution that is atomized directly onto metal surfaces. The system collects and manages overspray and drips separately, preventing contamination and eliminating traditional tanks.

Benefits and Performance

It allows easy upgrade from chromate to chrome-free pre-treatment with a compact design that places the tank off-line and the 12-inch long spray bar directly into existing tunnels.

news from alit world

News

ALIT USA to Present Chemical Paint Stripping Solutions at FABTECH 2025

📍 Booth D41156 – Chicago, IL 📅 September 8–11, 2025 FABTECH 2025, North America’s largest metal forming,...

Choosing The Right Commercial Paint Stripping Technology: Comparing Methods

Paint stripping is critical in many industrial operations, from surface preparation to maintenance and reconditioning. Choosing the...

ALIT Technologies Introduces Drizzling: Precision Non-Chromic Conversion Coating

ALIT Technologies expands its surface treatment solutions by introducing Drizzling, an innovative non-chromic conversion coating system designed...